Laser ablation is gaining popularity for medical device applications that require stripping of coatings on cylindrical components like hypotubes and guide wires.

Clean automated process improves production and increases throughput

Laser ablation is gaining popularity for medical device applications that require stripping of coatings on cylindrical components like hypotubes and guide wires. It is also being widely used for advanced surface treatments, including discoloration or foaming of plastics and darkening or annealing of metal parts. Offering a repeatable non-contact process, laser ablation is a clean, low dust (or no-dust) way to selectively remove wire layers or areas. It is also a fully automated process, with a very high yield compared to other methods.

Schematic representation of the laser processing

Laser processing applications

The key applications for laser ablation include:

- Layer/coating removal – The laser energy is used to evaporate, melt, or oxidise the existing layer. The laser can also be used to make a defined cut in the layer to enable easy removal of the layer, either by hand or by an automated method. Wire stripping requirements are constantly increasing, with both end-span and mid-span parts requiring selective removal. The newest applications include even smaller diameter wires, for example, those being used for transmitting electric signals for brain stimulation applications.

- Optional surface roughening – This can be useful for increasing adhesive adhesion or increasing the friction to make handling easier.

- Insulation layer removal – Electrical isolated wires can be stripped of the polyimide insulation isolation layer (tradename Kapton ® ). The Kapton absorbs certain wavelength of laser light effectively, leaving a clean metal surface for electrical contacting afterwards. The laser ablation process can also remove hydrophobic coatings, like polytetrafluoroethylene (PTFE, tradename Teflon ® ), silicone based coatings, and thermoplastic elastomers (TPE), including a wide range of polyamide (Nylon) coatings.

- Marker band annealing – The laser can be used to anneal stainless steel. This annealing darkens the metal to make a clear contrast with the clear surface of the (hypo-) tubes. This

can be used, for example, to create marker bands which a surgeon is able to use as a visual aid for guiding and placing catheters during medical procedures.

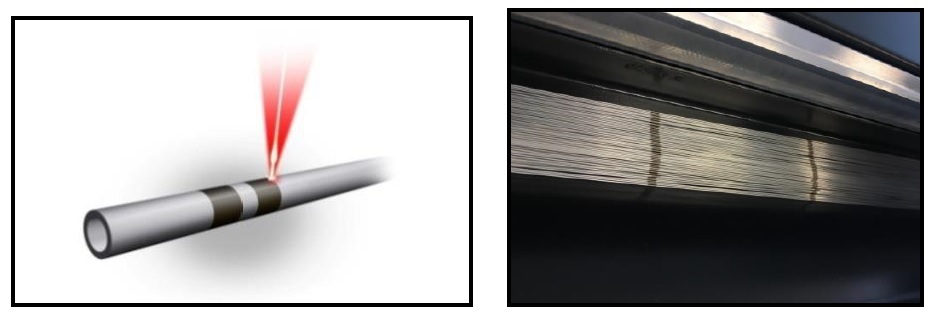

Figure 1 shows an example of a system producing marker bands by annealing the stainless steel tube. On the left is a schematic representation of the laser processing. On the right is a bundle of guidewires with the annealed markerbands.

Laser ablation preferred over mechanical or chemical removal methods

The laser ablation method removes material by directing a focused beam (minimal size around 25 microns in diameter. A larger size is easier to generate) by galvanometers, which are small fully programmable X and Y mirrors. This enables highly tailored removal, so parts or sections of wire insulation can be removed as needed. Changes to the size and location of the removed sections can be made on the fly by calling up pre-programmed recipes.

When used for wire stripping, laser ablation simply removes all the material from the wire as the polymer absorbs the light energy. The material is vaporized – effectively ejected away from wire. The laser does not affect the wire beneath the insulation, because the power levels needed to remove the insulation are much lower than those that would damage the metal wire. This advantage can be augmented by selecting a laser wavelength that is readily absorbed by the polymers, but reflected by the wire. The laser process imparts no physical force on the wire during the process, so delicate wires with diameters as small as 50 microns can be stripped.

Besides laser processing, other commonly used processes for removing wire layers include mechanical cut and peel, micro‐abrasive blasting (sandblasting), or chemical etching of the layers. However, the constantly decreasing diameter and wall thickness of wires used makes these competing stripping methods impractical, inefficient, or impossible. Laser ablation is simply cleaner, greener, and faster. In addition, laser ablation is a fully automated process with a very high yield compared to the other manual methods – nearly 100 percent. Speeds are fast, and are normally only limited by the amount of laser energy the wire can take. A wide range of lasers are available with different properties, enabling the end user to go as fast as their part allows.

Helping medical customers improve production

The laser ablation process has proven to be extremely successful for a variety of medical applications. For example, AMADA MIYACH EUROPE recently worked on a laser ablation project with an Irish medical device company for a hypotube used in a minimally invasive surgical tool for arteries. The application involved producing a marker band that enabled surgeons to know how far to insert the hypotube into the body. Sandblasting had initially been used to remove the nylon coating, but led to scratches between the tube and the wires. The sandblasting operation was replaced by laser ablation using a near infrared (NIR) laser, which performed selective removal of the coating. In addition, the NIR system removed the coating at the top of the tube, in preparation for gluing another part on top. Previously, this had involved grinding the part down to the bare metal.

Another successful laser ablation project was for a very fine medical spring made by a major German medical device company. The spring had an outer diameter of less than 1 millimetre and was used in minimally invasive surgical tools that operated through very small incisions. The pull wire inside the spring had to be welded to the spring; any wire coating remaining would be burned away, polluting the weld. The ablation system enabled the company to remove the coating to make the end of the spring weldable with a laser in a second process step.

Picking the right laser for the job

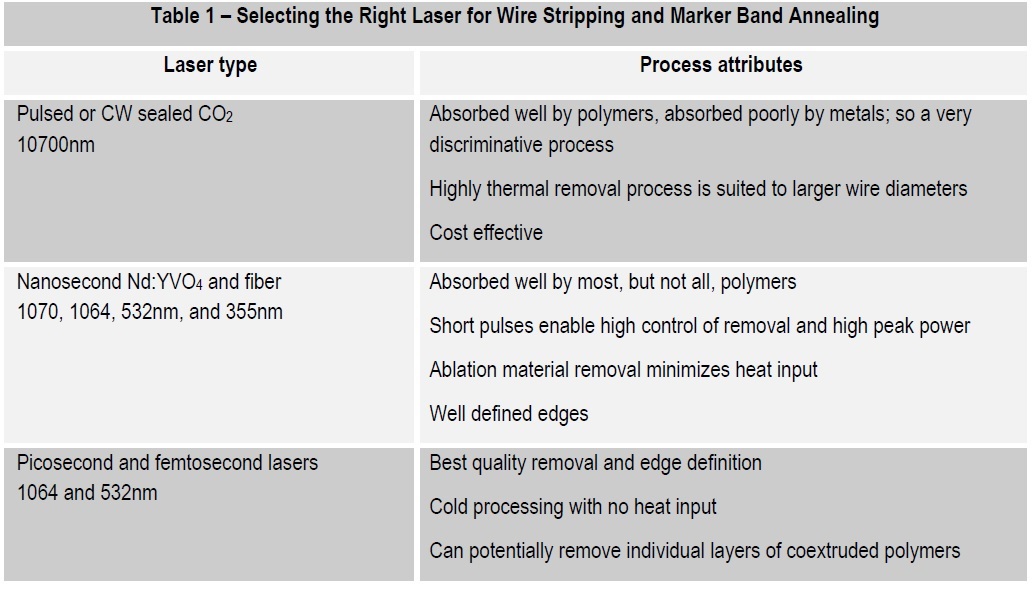

A number of different lasers can be used for wire stripping and marker band annealing, depending upon the particular wire diameter, insulation material (polyimide, Pebax®, PET (poly ethylene terephthalate), nylon, and fluoropolymers), and feature requirements.

Table 1 shows the lasers most commonly used for wire stripping and marker band annealing, listed by suggested order of consideration, from top to bottom. For each combination of material, wire diameter, and required features, there is a suitable laser that matches the desired criteria.

The sealed carbon dioxide (CO2) laser should always be considered first. With a wavelength of 10604 nanometres (nm), the CO2 laser is readily absorbed by every polymer, so it will work to a certain degree no matter what insulation material is used. Also, the CO2 laser is not readily absorbed by metals, so when all the insulation is removed and the laser hits the exposed wire, it has little effect for a relatively long time. Figure 2 shows a CO2 laser used for wire stripping.

If a CO2 laser cannot be used for reasons of heat input control, the nanosecond laser should be considered next, specifically those with 532nm and 355nm wavelengths. Nanosecond lasers produce pulses of around 20 nanoseconds, removing wire insulation material with a much less thermal process than that of the CO2 laser.

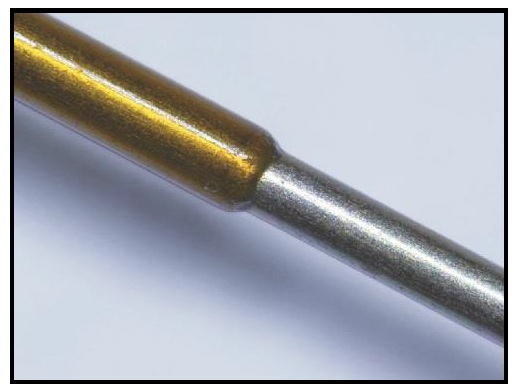

Figure 2. CO2 laser should always be considered first for wire stripping.

Figure 3. Nanosecond laser with a wavelength of 355 nm.

Figure 3 shows a wire that has been stripped using a nanosecond laser with a wavelength of 355 nm

The choice between the 532 or 355 nm is typically made based upon the insulation material; the 355nm is better absorbed by more polymers.

When extreme quality or minimal heat input is needed, consider the ultra-short pulse picosecond and femtosecond lasers. These two laser families produce pulse widths that are extremely short – picoseconds is 10-12 and femtosecond is 10-15 seconds. The pulses are so short that the coating evaporates and the material does not have time to conduct any heat from the process area into the surrounding material.

Laser wire stripping and annealing systems

Use of lasers for wire stripping and marker band annealing transforms a key step in the process to a lean operation. The key to the success of is in the development of the process. To make the right decision on which laser source and removal methodology works best, it is absolutely essential to test possible options in an application laboratory with a range of lasers. The resulting system solution will then be optimal in both process and implementation.

For example, AMADA MIYACHI EUROPE consults with customers using a multi-step testing process on wires and assemblies to simulate the system in a real high volume production environment.

Step 1 involves a simulation of whether the wires can be processed at high volumes. Typically, these systems involve processing a wire every 10 to 30 seconds. End users want to limit labour and increase throughput by using unassisted automatic wire loader and unloader machines. The test includes bundling up to 2000 wires to determine if the system can pick out a single wire, using either a magnetic or pneumatic picking tool, and feed it automatically into the laser ablation system.

Step 2 involves feeding the wire through the system. Optimal wire transportation through the system depends on the wire’s stiffness, weight and friction. Application experts pull the wire through the system and then measure the distance from the beginning or end point of wire to determine if the system can properly transport the wire. Several nozzles, feeding and transport wheels are tested to achieve the best result. Their materials, dimensions and coatings vary.

Step 3 is a test of the effectiveness of the actual ablation process once the wire is inside system and positioned on the right spot on the wire.

The testing process takes a few working days and uses AMADA MIYACHI EUROPE’s standard laser ablation system as the starting point. About half the wires and assemblies tested can be processed with the standard system, while the other half requires redesign and modification.

Figure 4 shows the MIYACHI EAPRO Automatic Hypotube Coating Removal System. The clean non-contact laser process reduces or eliminates dust during manufacturing, and can be used to process most plastic and metal parts fed as a bundle or on a reel.

Figure 4. MIYACHI EAPRO Automatic Hypotube Coating Removal System

The system is fully automated, saves time, and improves production processes, enabling higher throughput. It is extremely affordable compared to more expensive laser systems and other alternatives. Production yields are nearly 100 percent, and the laser process creates a cleaner cut with smoother edges when compared to grinding, as well as a much cleaner surface after processing.

The modular system is adaptable to specific product requirements. Customers can select the right laser for their process, including sealed CO2, nanosecond pulsed near infra-red 1070 nm, to ultraviolet (UV) 355nm and picosecond and femtosecond lasers. System options include automatic OK/NOK selection for output bin, in-line on-the-fly wire diameter measurement, and automatic wire length measurement.

Laser transforms wire coating ablation and marker band annealing to a lean, clean operation

Easily automated, the laser transforms a key step in the manufacturing process to a lean operation, reducing and optimizing human-dependent processes and providing consistent part quality. Using lasers rather than manual chemical-based processes also offers safety benefits from eliminating chemical use, reduces chemical handling and disposal costs, and supports a company’s ISO 14001 sustainability program.