Stratasys Ltd. announced it has partnered with Siemens Healthineers to carry out a landmark research project designed to develop new state-of-the-art solutions for the advancement of medical imaging phantoms for computed tomography imaging.

EDEN PRAIRIE, Minn. & REHOVOT, Israel--(BUSINESS WIRE)-- Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing and additive manufacturing solutions, today announced it has partnered with Siemens Healthineers to carry out a landmark research project designed to develop new state-of-the-art solutions for the advancement of medical imaging phantoms for computed tomography (CT) imaging.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231127909976/en/

Use of 3D printing may improve outcomes by providing 3D modeling to provider doctors with real scenarios to practice and consult with. (Photo: Business Wire)

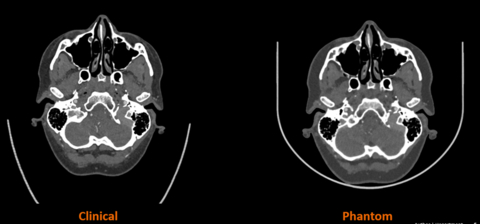

A critical tool in medical imaging and an almost universal resource in hospitals worldwide, CT phantoms are specialized devices used to evaluate and ensure the performance of CT scanners. Designed to simulate certain characteristics of the human body, phantoms enable the assessment of various core metrics, including radiation dose and image quality, aiding calibration and safeguarding consistent scanner performance. The joint development leverages Stratasys’ PolyJet™ technology in combination with its unique RadioMatrix™ technology, and Siemens Healthineers’ advanced algorithm aimed at translating scanned patient images into specific material characteristics with radiopacity of human anatomy. The solution will allow for tailored phantom manufacturing and the creation of ultra-realistic human anatomy characteristics with complete radiographic accuracy of patient-specific pathology not previously possible.

This joint project will transform how phantoms can be utilized in the medical field, and in certain cases even enable device manufacturers and academic facilities to replace human cadavers with 3D printed structures. Having this capability enables critical efficiencies and minimizes inevitable human variability. This work will also produce a critical body of research data, providing key insights for advancing CT system algorithms, driving materials development, and unlocking potential new application areas – as well as identifying future research opportunities.

“The current limitations of imaging phantoms have been a longstanding challenge for the radiology community,” said Erez Ben Zvi, Vice President Medical at Stratasys. “This partnership with Siemens Healthineers will enable us to jointly explore the vast possibilities of our radiopaque materials and 3D printing technologies to overcome these barriers.”

Beginning with the manufacturing of 3D printed phantoms for smaller-scale anatomies of the head and neck region, the research will involve the production of progressively larger and complex anatomies – leading up to the Phase One endpoint of 3D printing a heart model and of an entire human torso with complete radiographic accuracy.

“Knowledge gained from this project provides a breakthrough in medical imaging that will open up new avenues for uses when it comes to 3D printing and imaging,” said Lampros Theodorakis, Head of Computed Tomography Product & Clinical Marketing at Siemens Healthineers. “We are excited about the opportunities ahead of us as a result of this partnership and believe it will have long-term impacts for medical and academic applications.”

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products, healthcare, fashion and education. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys visit www.stratasys.com, the Stratasys blog, X/Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including the company’s websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Note to Editors: High-resolution images and additional information are available upon request from appropriately listed media contacts.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231127909976/en/

Investor and Media Contacts

Stratasys Corporate &

North America

Chris Reese

chris.reese@stratasys.com

+1 6651 357 0877

Investor Relations

Yonah Lloyd

Yonah.Lloyd@stratasys.com

+972 74 745 4919

Europe, Middle East, & Africa

Jonathan Wake / Samantha White,

Incus Media

stratasys@incus-media.com

+44 1737 215200

Brazil, Central America and South America

Erica Massini

Erica.Massini@stratasys.com

+55 (11) 2626-9229

Stratasys Corporate & Israel

Erik Snider

Erik.Snider@stratasys.com

+972 74 745 6053

Asia

Kalyani Dwivedi

Kalyani.Dwivedi@stratasys.com

+91 80 6746 2606

Source: Stratasys

Use of 3D printing may improve outcomes by providing 3D modeling to provider doctors with real scenarios to practice and consult with. (Photo: Business Wire)

Use of 3D printing may improve outcomes by providing 3D modeling to provider doctors with real scenarios to practice and consult with. (Photo: Business Wire)

View this news release and multimedia online at:

http://www.businesswire.com/news/home/20231127909976/en